Detonation Flame Arrester Series/Model C-FH |

Product Cut Sheet: Detonation Flame Arrester Series/Model C-FH |

|

Series C-FH

|

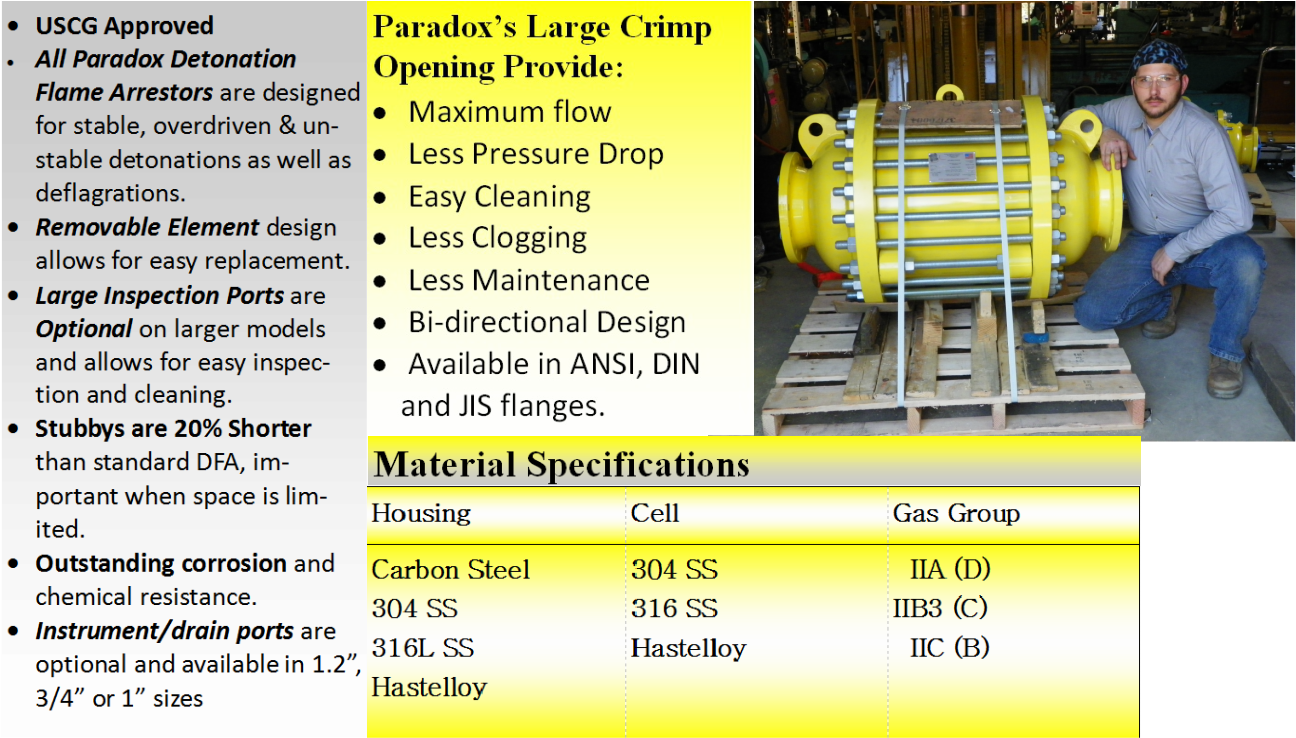

The Paradox Detonation Flame Arrestor represents the best technology for value in flame arrestor protection. They prevent flame propagation by absorbing heat and dissipating supersonic pressure waves, using multiple spiral wound crimped ribbon flame cells staged with turbulent creating screen sections.

These screen sections allow for much larger cells than that of competitive crimped ribbon flame arrestors, allowing maximum flow with maximum protection. They provide protection against flame propagation in piping systems that are manifolded or have long run-up distances. Paradox’s detonation flame arrestor element technology dampens the high velocities and pressures associated with deflagrations and detonations while quenching the flame front and providing larger flame channels which requires less frequent maintenance due to clogging and greater ease in cleaning when service is required. This translates to less down time. Our detonation arrester element offers maximum flow to pressure drop characteristics enhancing the value of our product in any system.

Our detonation arresters are typically used for extended pipe length or multiple pipe bend configurations to stop high pressures and flame velocities associated with detonations and over-driven detonations. In addition, it stops confined and unconfined, low and high-pressure deflagrations. All Paradox units are bi-directional and are proven to stop an ignited flammable vapor mixture approaching form either direction that can be traveling at subsonic or supersonic velocities.

Designed with flanged connections, this detonation flame arrestor provides the option of the removal of the flame cell (element) for easy cleaning and replacement without disconnection of the pipe connection flanges. Standard housing construction is carbon steel and stainless steel. The detonation flame arrester element is available in 304SS and 316SS & Hastelloy

These screen sections allow for much larger cells than that of competitive crimped ribbon flame arrestors, allowing maximum flow with maximum protection. They provide protection against flame propagation in piping systems that are manifolded or have long run-up distances. Paradox’s detonation flame arrestor element technology dampens the high velocities and pressures associated with deflagrations and detonations while quenching the flame front and providing larger flame channels which requires less frequent maintenance due to clogging and greater ease in cleaning when service is required. This translates to less down time. Our detonation arrester element offers maximum flow to pressure drop characteristics enhancing the value of our product in any system.

Our detonation arresters are typically used for extended pipe length or multiple pipe bend configurations to stop high pressures and flame velocities associated with detonations and over-driven detonations. In addition, it stops confined and unconfined, low and high-pressure deflagrations. All Paradox units are bi-directional and are proven to stop an ignited flammable vapor mixture approaching form either direction that can be traveling at subsonic or supersonic velocities.

Designed with flanged connections, this detonation flame arrestor provides the option of the removal of the flame cell (element) for easy cleaning and replacement without disconnection of the pipe connection flanges. Standard housing construction is carbon steel and stainless steel. The detonation flame arrester element is available in 304SS and 316SS & Hastelloy